The Chroma 19055 Withstand Voltage Analyzer is designed for withstand voltage testing and analysis. With 500VA of power and a maximum output of 5kV/100mA AC, it meets the needs of high power withstand voltage testing and complies with the equipment requirements of EN50191 (for more information, please refer to the application note).

In addition to the basic AC withstand voltage, DC withstand voltage, and insulation resistance tests, the 19055-C series also incorporates the newly developed Corona Discharge Detection (CDD) function, which can be detected by Breakdown Voltage Analysis:

- Corona discharge Start Voltage (CSV)

- Flashover Start Voltage (FSV)

- Breakdown Voltage (BDV)

For contact checking during testing, in addition to the original patented design of OSC Open Short Check, a new High Frequency Contact Check (HFCC) is added to conduct contact checking before high-voltage output to enhance test reliability and efficiency.

In order to consider the user, Chroma 19055 is equipped with a large LCD display screen for easy operation and judgment. Adding GFI human body protection circuit and Floating safety output design to protect the operator's safety, so that you can operate without worry.

measurement technique

BREAKDOWN / FLASHOVER / CORONA DISCHARGE TECHNOLOGY

What is a bad voltage withstand? Most electrical safety standards state "During the test, no flashover or breakdown shall occur", meaning that no electrical flashover or breakdown shall occur during the voltage withstand test. But nowadays, insulation failure (Failure) and discharge (discharge) have become the most important issues for all kinds of insulating materials or voltage components. Because of the high correlation between discharge and insulation capability, discharge detection is not only a safety issue, but also the main key to controlling product quality. If the nature of material discharge to categorize, discharge can be divided into three types: corona discharge (Corona discharge), spark discharge (Glow discharge), arc discharge (Arc discharge).

Corona Discharge

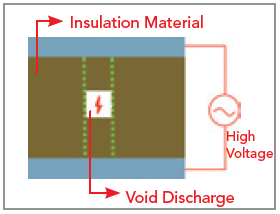

When the two electrodes are subjected to higher voltage, the electric field strength is relatively large, when this effect is greater than the gas ionization potential energy (Ionization Potential), the gas on the surface of the material occurs instantaneous ionization phenomenon, at this time, there will be visible light and temperature rise phenomenon. Long-term corona discharge and temperature rise may cause material qualitative change (Qualitative Change), which in turn leads to insulation deterioration (Insulation Deterioration), so that the degree of insulation resistance decreases, and ultimately insulation failure occurs. Figure 1 shows the schematic diagram of corona discharge. Since corona discharge generates high frequency transient discharge, it can be detected by high frequency power measurement.

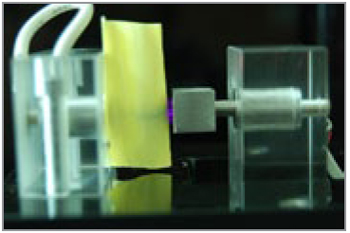

▲ Figure 1: Schematic diagram of corona discharge

Glow Discharge & Arc Discharge

Insulating material internal or surface due to high voltage generated electrical discharge, the object to be tested to lose the original insulation properties, the formation of transient or discontinuous discharge, the seriousness of the carbonization will lead to a conductive path or product damage. As can be seen in Figure 2 on the right, the instantaneous discharge and can not be determined by the leakage current flow to detect bad, must be determined by the rate of change of the test voltage or leakage current to detect bad. Therefore, electrical flashover (Flashover/ARC) detection is one of the indispensable inspection items for high voltage testing.

▲ Figure 2: Schematic diagram of instantaneous transient discharge

For different discharge environments, Chroma 19055 provides corresponding discharge detection techniques, including Corona discharge detection (19055-C only), ARC/Flashover detection, and leakage current determination (Breakdown), which can be the best tool for R&D or QA units when testing and analyzing voltage withstand. These functions can be the best tools for R&D or QA units when testing and analyzing voltage withstand.

▲ Figure 3: Discharge Level Analysis (DLA) Model

BREAKDOWN VOLTAGE ANALYSIS (BDV)

The withstanding voltage of a passive component is determined by the material and process. In order to improve the insulation quality and capability of the components, it is necessary to analyze the degree of discharge, which includes corona discharge, electrical flashover/ARC, and insulation breakdown, and the Chroma 19055 Withstanding Voltage Analyzer has a new function of Breakdown Voltage Analysis (BDV). Voltage Analysis (BDV) function has been added to the Chroma 19055 Voltage Analyzer. By setting the start voltage, end voltage, number of times and time of the climb, the degree of discharge is analyzed.

The Breakdown Voltage Analysis (BDV) function provides a three-stage judgment method, which can be set to detect corona discharge (Corona limit), electrical flashover detection (Flashover/ARC), and insulation breakdown detection (Breakdown, high limit). When there are defects in the test, the Chroma 19055 will display the withstanding voltage according to the limit values at different stages of the discharge, which represent the Corona discharge Start Voltage (CSV), Flashover Start Voltage (FSV), and Insulation breakdown detection (Breakdown, high limit). Start Voltage (CSV), Flashover Start Voltage (FSV) and Breakdown Voltage (BDV). With these test results, researchers can analyze and study the product to improve the weaker parts of the component insulation.

Prevent contact failure during product testing High Frequency Contact Check (HFCC) & Open Short Circuit Detection (OSC)

High Frequency Contact Check (HFCC) is a new contact checking technology developed by Chroma, which is designed to be used in AC/DC withstand voltage test program to check for poor contact during the withstand voltage test, the test frequency of HFCC is increased to about 500KHz, which can greatly improve the accuracy of contact checking and effectively enhance the production line productivity. The test frequency of HFCC is increased to about 500KHz, which can greatly improve the accuracy of contact checking and effectively increase the production efficiency of the production line.

If open-circuit phenomenon occurs during the withstand voltage test, it will lead to misjudgment of defective products as good products; if short-circuit phenomenon occurs, it can be known and screened in advance, reducing the damage to the fixtures and equipment, and saving the test cost.

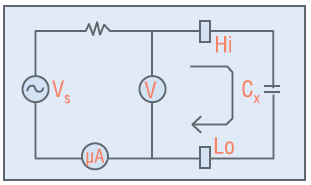

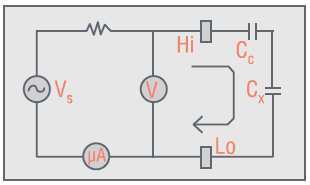

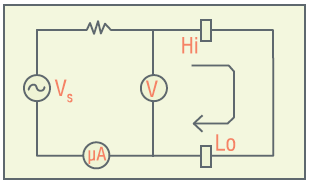

General withstand voltage test products are capacitive (Cx), in the normal state may be in tens of pF to several μ F between, once the connection breaks in the broken interface will form a small capacitance (Fig. 4.2 of Cc), generally less than 10pF, and show the overall capacitance is far lower than the normal product phenomenon. When the object to be measured is short-circuited or close to short-circuited, the capacitance will be much higher than normal. Therefore, the capacitance change can be used to determine the upper and lower limit values to reduce the occurrence of poor contact problems in the production line.

▲ Figure 4.1: Normal Test Status |

▲ Figure 4.2: Test loop open Cm = Cc * Cx / (Cc + Cx) << Cx |

▲ Figure 4.3: Test loop short circuit Cm >> Cx |

Personnel Safety Protection Design Output Circuit Function (FLOATING OUTPUT) with GROUND FAULT INTERRUPT (GFI)

The purpose of safety testing is to protect the user of the product. The Chroma 19055 has two types of operator-protected safety designs to choose from: Floating Output and Ground Failure Interrupt (GFI).

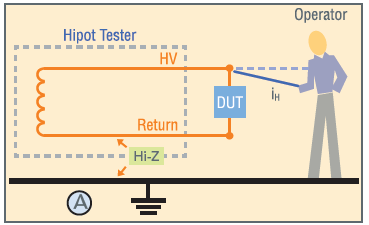

In order to allow testers to use the safety test equipment safely, Chroma has developed the Floating Output circuit with a new technology and complies with the EN50191 equipment safety standard. In the Floating output condition, there is a high impedance to the ground, and no matter the tester touches any of the withstand voltage test terminals, the leakage current to ground iHNone will be greater than 3.5mA, and the tester will not be electrically harmed. As shown in Figure 5.

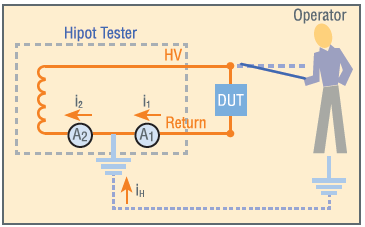

The GFI function is another human protection circuit. As shown in Fig. 6, i1 and i2 can be obtained from ammeters A1 and A2 respectively; when the operator is electrocuted, the ammeters measure different values, and the difference is i1 - i2 = iH , when iHIf it is too high, it will be judged as bad GFI and will cut off the output signal immediately to protect the user's safety.

▲ Figure 5: Schematic of Floating Output Circuitry |

▲ Figure 6: Schematic of the GFI Ground Failure Interrupt Circuit |

Product Applications

Chroma 19055-C voltage analyzer is equipped with Corona Discharge Detection (CDD) to detect corona discharge and reduce the incidence of customer complaints. It can also be used to find the corona discharge start voltage (CSV), electrical flashover start voltage (FSV), and insulation breakdown voltage (BDV) using the breakdown voltage analysis function (BDV), which provides reference data for verification of insulation capability during the product development stage and for the reliability of the product manufacturing process.

Corona discharge detection at normal voltage

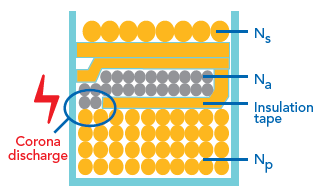

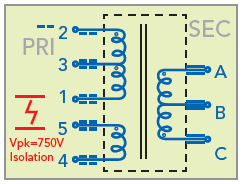

transformersWhen electronic products in the normal voltage use, if the internal primary circuit insulation is poor, resulting in the primary end of the winding in the corona discharge state for a long time, after a period of time, will certainly affect the insulation capacity. Power transformer is an example, some of the current power transformer design, more will retain a set of reference coils for other circuits, as shown in Figure 7.2, in the long-term Vpk = 750V, when the production process is poor, such as poor processing of insulating tape, casing, etc., resulting in a persistent corona discharge occurs, the primary windings between the resistance of the insulation will have an impact on the ability to carbonize the varnish and burned.

▲ Figure 7.1: Poor processing of insulating tape |

▲ Figure 7.2: Poor insulation due to poor transformer primary process |

motor (loanword)Rotary motors, such as industrial motors or electric vehicle motors, require high durability and reliability due to the long operating time and the wide variation of temperature and humidity in the operating environment. Temperature and humidity are also factors that affect insulation. If corona discharge occurs between coils and coils, or between coils and cores, it will lead to long-term temperature rise and material quality changes, resulting in insulation deterioration. Adding the corona discharge test function to the withstand voltage test raises the bar on insulation quality, identifies products with poor insulation capability, and effectively reduces the chance of defects due to long-term use.

▲ Figure 8: Corona discharge inside the motor

Capacitor/Insulating Material High Voltage Withstand TestsHigh-voltage withstand testing is often used in the verification of high-voltage capacitors, safety capacitors, and insulating materials. When there are cracks or bubbles in the dielectric between the insulating media due to the manufacturing process, once the withstand test is conducted, different electric field states will be formed, and corona discharge phenomenon will occur. Long-term changes in the dielectric state will result in poor insulation and quality problems.

▲ Figure 9: Schematic diagram of bubble discharge

Product Features

- 500VA output

- Floating output design to meet EN50191 requirements

- Corona corona discharge detection (19055-C)

- Flashover Electrical Flash Detection

- BDV crash voltage analysis

- Patented HFCC high frequency contact detection

- Patented OSC open/short circuit detection

- GFI Human Body Protection Circuit

- Standard RS232 & HANDLER interface

- Optional GPIB interface

- Panel lock function in case of failure

- Programmable voltage outputs and test limits

- Support A190301 High Voltage Scanning Fixture

| model number | relate (a story or information) |

| 19055 | Withstand Voltage Test Analyzer AC/DC/IR |

| 19055-C | Withstand Voltage Analyzer AC/DC/IR (with Corona function) |

| A190301 | 8HV High Voltage Scanning Fixture |

| A190355 | 19" frame headset |

| A190356 | GPIB Interface |

| A190708 | ARC (Flashover) Verification Fixture |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.