Chroma 17040 battery module test system is designed for high-power secondary battery pack test and the development of high-precision charging and discharging equipment, with energy recovery function, can save a large amount of power consumed in the discharge process, even if the dynamic charging and discharging, but also to ensure that the grid side to maintain stability, not because of harmonic pollution affecting other equipment. It also recycles the power generated from the battery pack discharge to the power grid for reuse, solving the traditional problem of energy wastage of the equipment discharge and the difficulty of space heat treatment, which is in line with the demand for environmental protection.

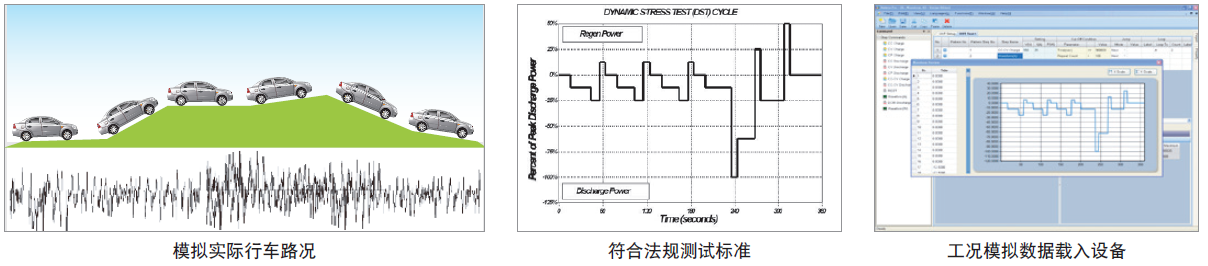

The 17040 system is equipped with channel paralleling and dynamic condition simulation functions. The paralleling function can increase the maximum charging and discharging current and power, which increases the efficiency and flexibility of the equipment, and achieves a high utilization rate of the equipment. The dynamic simulation function allows users to load the battery waveforms from the road spectrum and select either current or power modes to meet the requirements of different standards (NEDC/FUDS). The bi-directional architecture ensures that the current is not interrupted during the charging and discharging transitions to accurately simulate driving conditions and comply with various international test standards such as ISO, IEC, UL, GB/T, and so on.

The 17040 system is equipped with Battery Pro software with flexible editing functions, which allows independent testing of each channel and meets the testing needs of secondary battery modules with high stability and safety, and supports power failure reset function to ensure uninterrupted test data.

A number of safety protection mechanisms are designed for battery testing, and abnormal signals such as over-voltage, over-current, over-temperature, and external parameter judgment are automatically detected during the testing process to ensure the safety of the testing process. When each channel detects abnormality, it will stop charging and discharging protection measures, and it also has the function of saving and resuming the test data in case of power failure, so as to prevent any potential factors of data leakage.

Safety - Enhanced Risk Management

- Test conditions and cut-off/protection conditions can be loaded directly into the charger/discharger for execution, and multi-layer protection can be achieved through internal software/hardware.

- Integration of external hardware to obtain real-time monitoring parameters, such as BMS, Data Logger, Chamber, I/O signals, to achieve alarm/cut-off/power-down protection function.

- Through the BMS communication reading and Data Logger measurement, it can monitor the voltage/temperature values in the battery pack and make real-time judgment and protection actions according to the set values.

- Built-in multiple alarm/protection modes: OVP, UVP, OTP, WIR_LOSS, CAL_ERR, POW_ERR, RM

Precision - Improving Product Quality

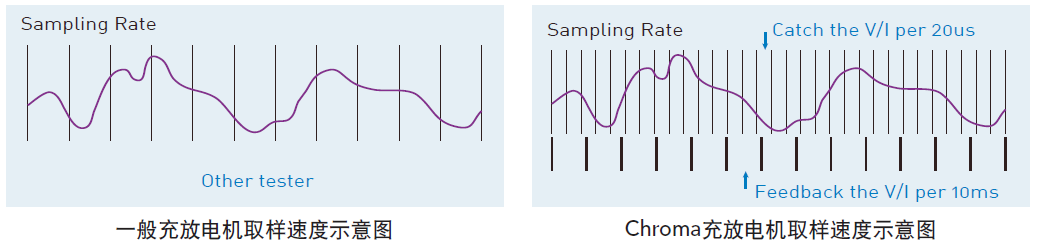

- High-frequency sampling and measurement technology: the fastest sampling rate of 50kHz, to ensure dynamic measurement accuracy.

- Voltage accuracy: ± (0.02% of rdg. ± 0.02% of F.S.)

- Current accuracy: ±(0.05% of rdg. ± 0.05% of r.n.g.)

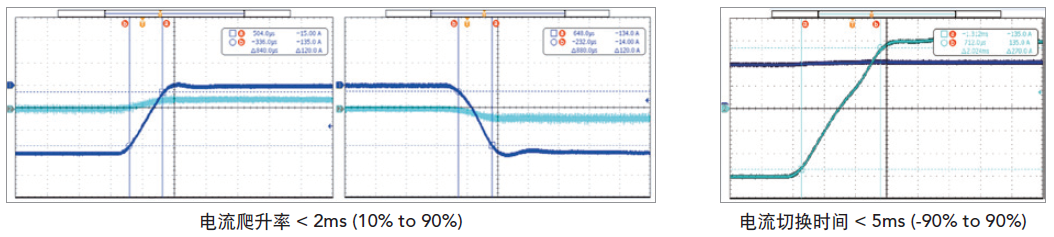

- Fast response test technology: current switching time of 5ms (-90% to 90%), suitable for a variety of test application requirements

- Automatic voltage/current file switching function: can be divided into multiple files, with the dynamic change process of large or small current, automatically adjust the correct file to achieve the optimization of measurement accuracy.

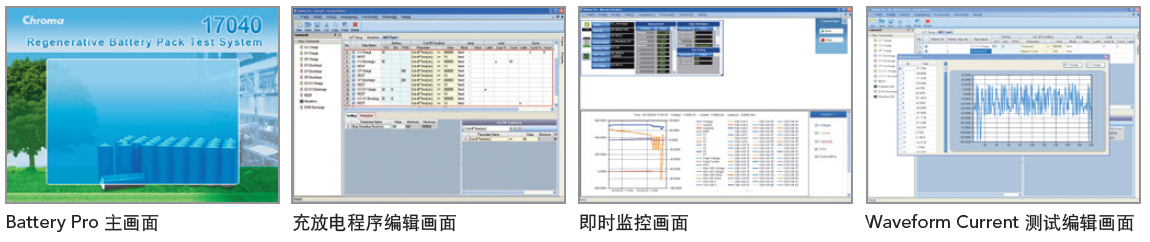

- Supports Waveform test function to simulate the current or power state of actual driving conditions, and supports NEDC, FUDS, HPPC and other regulatory test standards.

High Frequency Sampling and Measurement Technology

In general, battery chargers and dischargers directly use software to read current values for capacity calculation, however, the data reading speed of the software is limited, which will result in too large an error in capacity calculation for dynamic current, Chroma provides more accurate capacity calculation by increasing the V/I sampling rate and integrating it twice to provide more accurate capacity calculations without missing data when the current is changing, and is not affected by the data transfer rate.

- V/I sampling rate 50kHz (one sample every 20μs)

- Segmented integral mode operation: Integration of I - capacitance; Integration of V x I - energy.

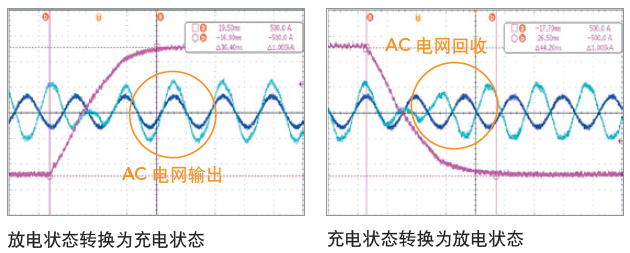

Fast Response Testing Technology

The fast response of the current can be achieved at the same time to optimize the charging and discharging mode switching control, to avoid the test process damage to the object to be tested.

- Current Ripple Noise <0.5%, Overshoot <1%

Dynamic condition simulation function

Battery packs are used in a rapid and irregular current charging and discharging state, through the simulation of the working conditions, the battery pack's state of use can be truly reflected in the battery.

- Simulate the dynamic charge/discharge waveform of the actual battery, in this dynamic current mode (Waveform), the maximum discharge and maximum charge current conversion time is only 5ms.

- The work step can be set to read the Excel file of current/power waveforms stored in the specified computer.

- 720,000 points per channel for long time dynamic testing

Benefits - Reduced operating costs

- Integration/customization of hardware and software, e.g. BMS, Data logger, thermostat, external signals, HIL (Hardware in the Loop).

- Provides a variety of external signal interfaces (CANbus, Ethernet, Analog I/O) to support Hardware-in-the-Loop (HIL) test platforms.

- Parallel connection function between systems, up to 360kW, 900A (optional)

- Battery charger/discharger and battery emulator functions.

- Highly efficient discharge energy recovery technology

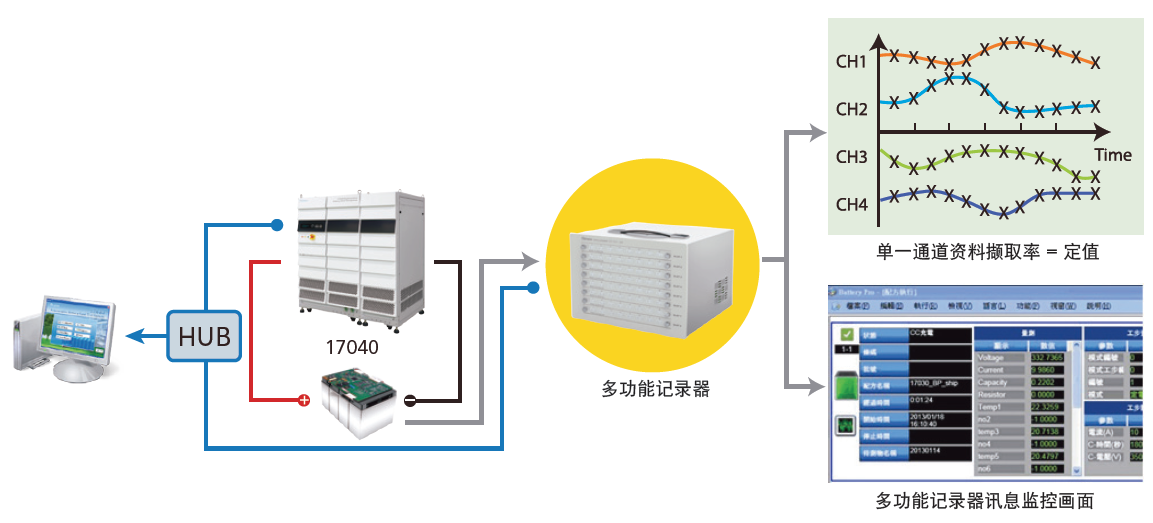

Multi-function recorder integration technology

The 17040 system integrates a multi-function logger through the software to read multiple voltage and temperature records during charging and discharging, and the conditions can be converted to protection start conditions or cut-off conditions. The multifunction logger can achieve simultaneous sampling of all channels with a fastest data acquisition speed of 10ms, and the 17040 system can support up to 120 channels of multifunction loggers.

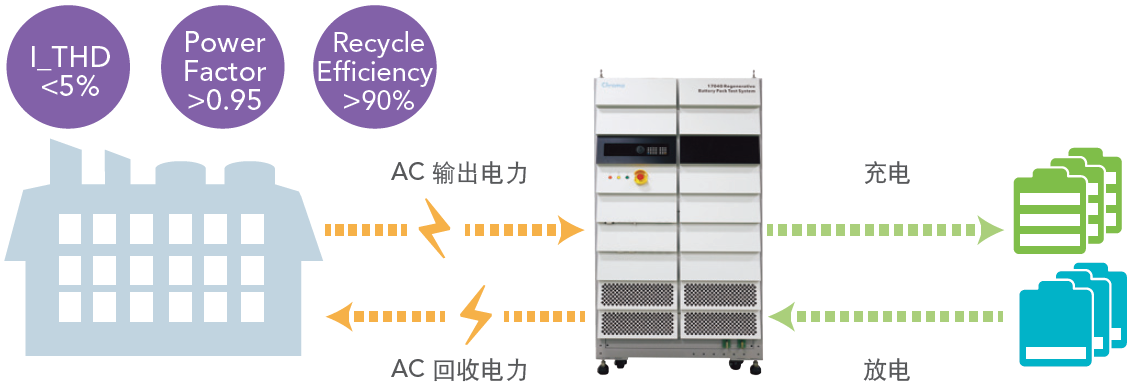

Discharge Energy Recovery Technology

- Bi-directional circuit architecture for precise control of current reversal.

- Discharge energy recovery function (efficiency >90%)

- Steady State Energy Recovery Characteristics: Compliant with Solar Recovery Grid Standard, Current THD 0.95

- Dynamic energy recovery feature: real-time phase conversion of instantaneous current, avoiding grid pollution

- Energy recovery to the grid process, AC current waveforms smooth and real-time phase transition is completed, which can avoid the test misjudgment or cause the grid to be contaminated affecting other equipment.

Dual mode application switching

- Charger/discharger mode: Battery Pro software interface for power battery pack testing.

- Battery Simulator Mode: Battery Simulator software interface for motor drive/charging post testing.

Battery charging and discharging software - Battery Pro

The software platform of Chroma 17040 test system, Battery Pro, meets the test requirements of secondary battery packs with high stability and safety, and has the function of saving and recovering data in case of power failure, preventing the possibility of any data leakage.

- Real-time monitoring: system test status can be viewed in real time without waiting, channel data and system integration data can be viewed at the same time.

- Icon management: Channel test status is managed through different icons, easy to see, easy to understand, and immediately understand the test status against the status description.

- Privilege setting: user operating privileges can be set to facilitate management

- Fault record tracking: Independent record of channel anomaly status

Integrated CANbus/SMbus/LIN communication function

- Vector.dbc file can be loaded directly, allowing users to quickly and easily complete the BMS monitoring settings.

- The user can set the required message information according to the BMS communication protocol.

- The read BMS data can be converted into protection conditions or cut-off conditions during the test.

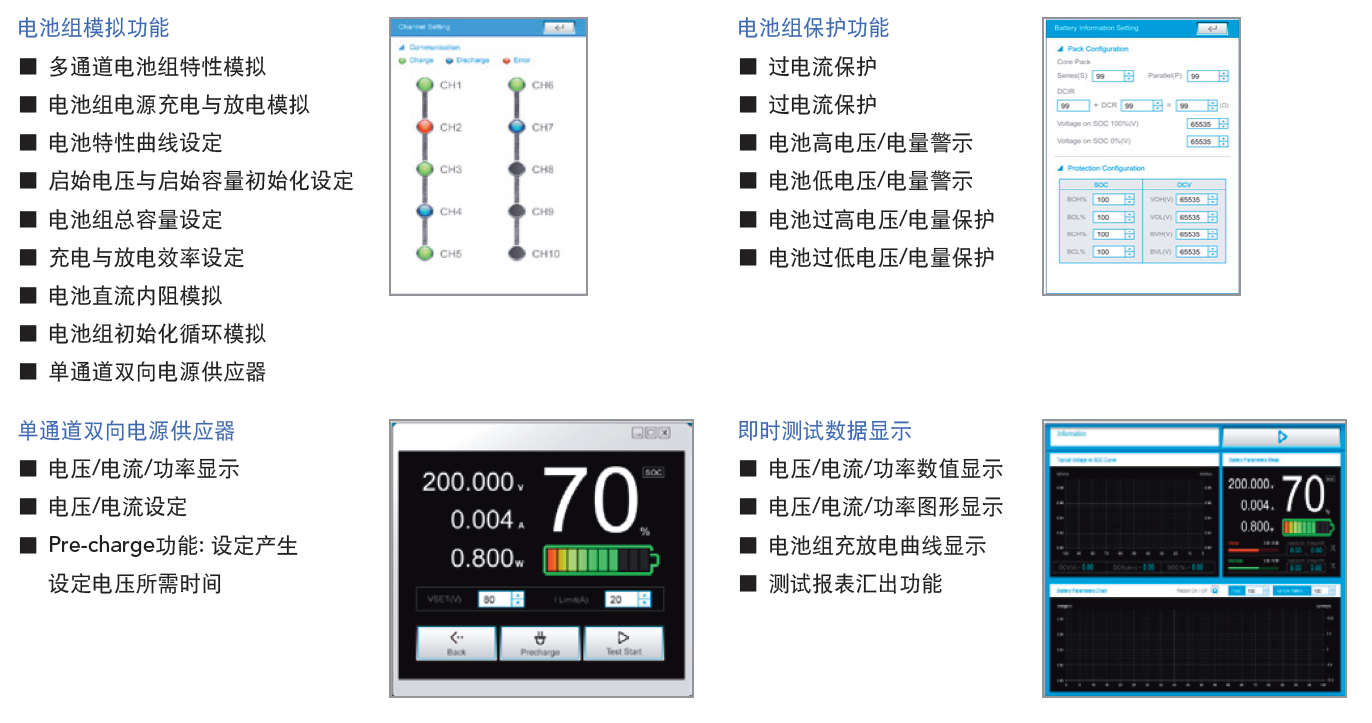

Battery Simulator Software - Battery Simulator

17040 has a battery charger/discharger and battery simulator two functions, can be used to test the battery pack and test and battery pack connected to the relevant products, products in the R & D design, the supplier battery is not yet in place, through the battery simulator function, to confirm its system function is normal, and also program control of the state of the different batteries (SOC status), and can download the different battery curves, test the product charge/discharge status, in advance to do the product with the battery test evaluation, can be applied to automotive start-stop system motor drive, light electric vehicle electronic controller, car chargers and other tests. It can also download different battery curves to test the charging and discharging status of the product and evaluate the testing of the product with the battery in advance, which can be applied to the testing of automobile start-stop system motor driver, light electric vehicle electronic controller, car charger and so on.

Battery Pro Battery Emulator Interface

Optional battery emulator function, bi-directional voltage source can be charged or discharged, can set the battery capacity / DC impedance / download the V-SOC curve, suitable for use in testing chargers, inverters and motor drives, with special software for battery emulator.

Product Features

- Comply with international standard test for power battery: IEC, ISO, UL, GB/T, etc.

- With battery discharge energy recovery and reuse function (Eff. >90%, PF >0.95, I_THD <5%)

- Voltage/current multi-file automatic switching function

- Highly accurate current/voltage measurement

- ±(0.05% rdg + 0.05% F.S.)

- ±(0.02% rdg + 0.02% F.S.)

- Current creepage rate (10%~90%)

- 1ms (<300kW)

- 10ms (300~600kW)

- Dynamic (current/power) condition simulation testing: NEDC, FUDS, HPPC, etc.

- With channel paralleling function

- Report data analysis function

- Supports power failure reset test function

- Automatic protection function for test abnormality

- Battery emulator function (optional)

- High-power testing equipment

- Voltage range: 60 ~ 1000V

- Current range: 0 ~ 1500A

- Power range: 0 ~ 600kW

- Customized Integration Functions

- Integrated temperature control box

- BMS data reading judgment

- Multi-channel voltage/temperature acquisition

Application Areas

- Power Battery Module

- Energy Storage Battery Systems

- motor driver

- Energy Storage Power Control System

| model number | relate (a story or information) |

| 17040 | Energy Recovery Battery Module Test System |

| 17040 | Energy Recovery Battery Module Test System 60kW/1CH |

| 17040 | Energy recovery battery module test system 120kW/1CH |

| 17040 | Energy Recovery Battery Module Test System 120kW/2CH (60kW per CH) |

| 17040 | Energy recovery battery module test system 180kW/1CH |

| 17040 | Energy recovery battery module test system 250kW/1CH |

| 17040 | Energy Recovery Battery Module Test System 250kW/2CH (125kW per CH) |

| 17040 | Energy recovery battery module test system 300kW/1CH |

| 17040 | Energy recovery battery simulator 60kW/1CH |

| 17040 | Energy recovery battery simulator 120kW/1CH |

| 17040 | Energy recovery battery simulator 180kW/1CH |

| 17040 | Energy recovery battery simulator 250kW/1CH |

| 17040 | Energy recovery battery simulator 300kW/1CH |

| A170201 | Industrial computer for battery charge/discharge test system |

| A170202 | Battery Simulator Software |

| A170400 | Battery Pro Charge and Discharge Test Software |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.