The Chroma 87001 Battery Cell Simulator is a multi-channel, high-precision, and programmable bi-directional DC power supply with both voltage and current source functions, which can be used as a multi-channel DC power supply or electronic load. Each unit has 16 channels, and the voltage and current of each channel can be set through the software interface.

The 87001 Battery Cell Simulator accurately simulates lithium-ion battery cells, replaces battery cells in a reliable and safe environment, and tests battery management units (BMUs) or sub-systems with battery cell measurement cells (CSCs) for applications related to electric vehicles and energy storage batteries.

The 87001 simulator can simulate 480 battery packs (240S2P, voltage <1,000V) in series with cell voltage isolation channels, in order to simulate the power supply characteristics of the battery cells to absorb and provide energy; at the same time with the ability to measure and monitor the voltage and current, each channel to provide 0 ~ 5V voltage regulation and 0 ~ 5A bidirectional current function, the channel has a series and parallel function, the channel has a series and parallel function, the current can be increased according to the number of parallel. The current can be increased in parallel according to the number of channels.

The 87001 Battery Cell Simulator can be used for stand-alone Battery Management Units (BMUs) with separate software interfaces, or for master-slave Battery Management Systems (BMSs), and can be integrated into a BMS automated test system for fully automated test procedures to quickly complete product validation.

Paired with a customized Chroma BMS automated test system, the 87001 simulator provides temperature sensor simulation for each battery cell for highly accurate temperature simulation, and transmits the temperature status of each cell to the battery management system (BMS) for testing.

Chroma 87001 battery cell simulator is equipped with a variety of protection functions such as: overcurrent protection (OCP), overvoltage protection (OVP), undervoltage protection (UVP), fan abnormal protection (FANFail), and output circuit compensation voltage, etc., to provide users with a safe test environment.

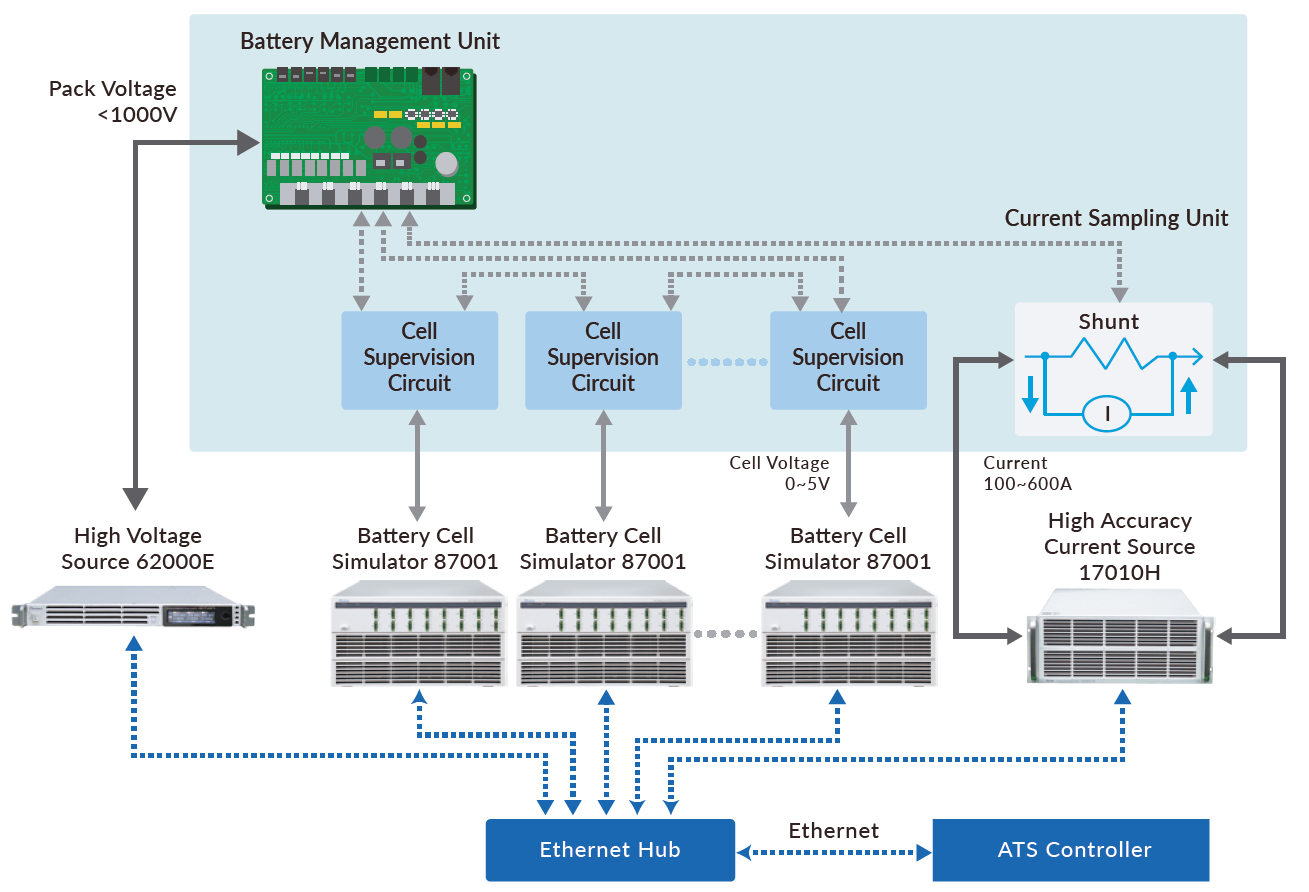

Battery Management System Master-Slave Application Architecture Diagram

The Chroma 87001 battery cell simulator can simulate the current, voltage, and temperature variations of a wide range of battery cells. The figure below shows a demonstration architecture for integrating a battery cell simulator into a BMS automated test system for a battery management system with built-in subsystem measurement units.

Cell status parallel and series operation modes

- When the user needs more than 16 strings of battery cells, more than one battery cell simulator can be connected in series, and the upper limit of the number of supported units is 15 units 87001

- Users can also connect each 87001 independently through the Ethernet HUB, the upper controller in the state of sufficient Ethernet bandwidth, remote synchronous control applications, multiple 87001 at the same time to give the command to change the voltage, a single voltage control response time <10ms.

- Hardware configuration can be configured up to 240 series and 2 parallel (voltage <1,000V), the simulator can support the coexistence of channel series and channel parallel, parallel state, the battery cell simulator with automatic equalization of current design

Note: Control voltage response time (phase delay time) = upper controller command sending time + 87001 processing command time + voltage rise/fall time

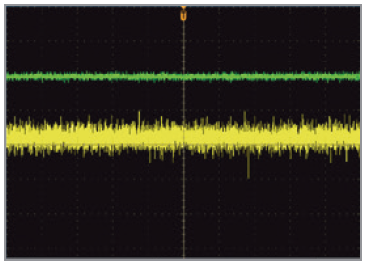

Precise voltage/current measurement

Chroma 87001 battery cell simulator provides voltage source mode and bi-directional current source mode, with built-in 16-bit high precision A/D converter, voltage measurement accuracy of ±1mV (0.02%F.S.), and voltage measurement resolution up to 0.1mV.

Aiming at the market trend of active and passive balancing design, the measuring current is divided into 4 grades: 0~9A (10mA).

Programmable Sequence Functions

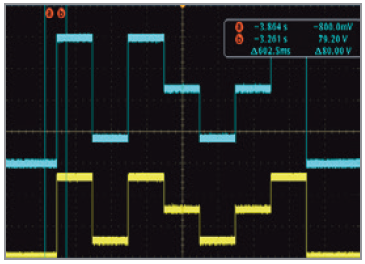

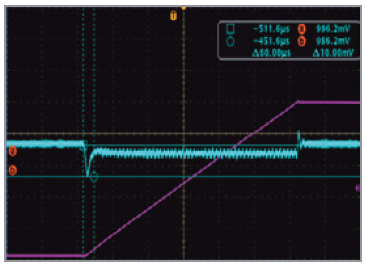

87001 Battery Cell Simulator is a 16-channel battery cell simulator. Through the software interface, users can set the voltage and current limit status of each channel, and program the output voltage rise and fall, and synchronize the start-up of each channel; the advantage of low output noise is that it truly presents the DC characteristics of the battery cell without ripple, and it can quickly return to give a stable DC output when the dynamic load is changing and reduce the surge voltage generated by load changes that may damage the object to be tested. At the same time, it reduces the surge voltage generated by the load change and damages the object to be tested. For non-static products or test applications, it can supply a stable DC voltage source in time.

The Chroma 87001 battery cell simulator provides a high-speed, programmable dynamic bi-directional load mode with less than 100us load variation capability to simulate a variety of different real-world pull current waveforms.

▲ Synchronized start-up time difference between channels <2ms

▲ Voltage change on all channels

▲ Low output noise <0.35 mV rms

▲ Stabilized DC output from load change

▲ High-speed voltage response <1ms

Support for system integration

- Chroma provides two kinds of commands (SCPI through the network interface and CANbus command through the CANbus interface), Labview driver, Labwindow driver and other languages, allowing users to develop their own applications to control the 87001 battery cell simulator.

- Chroma's system integration capabilities provide customized system-integrated automated test systems for BMS functional testing.

Note: The SCPI command is used to support 1ms information sampling to verify the passive balance switch status.

remote control function

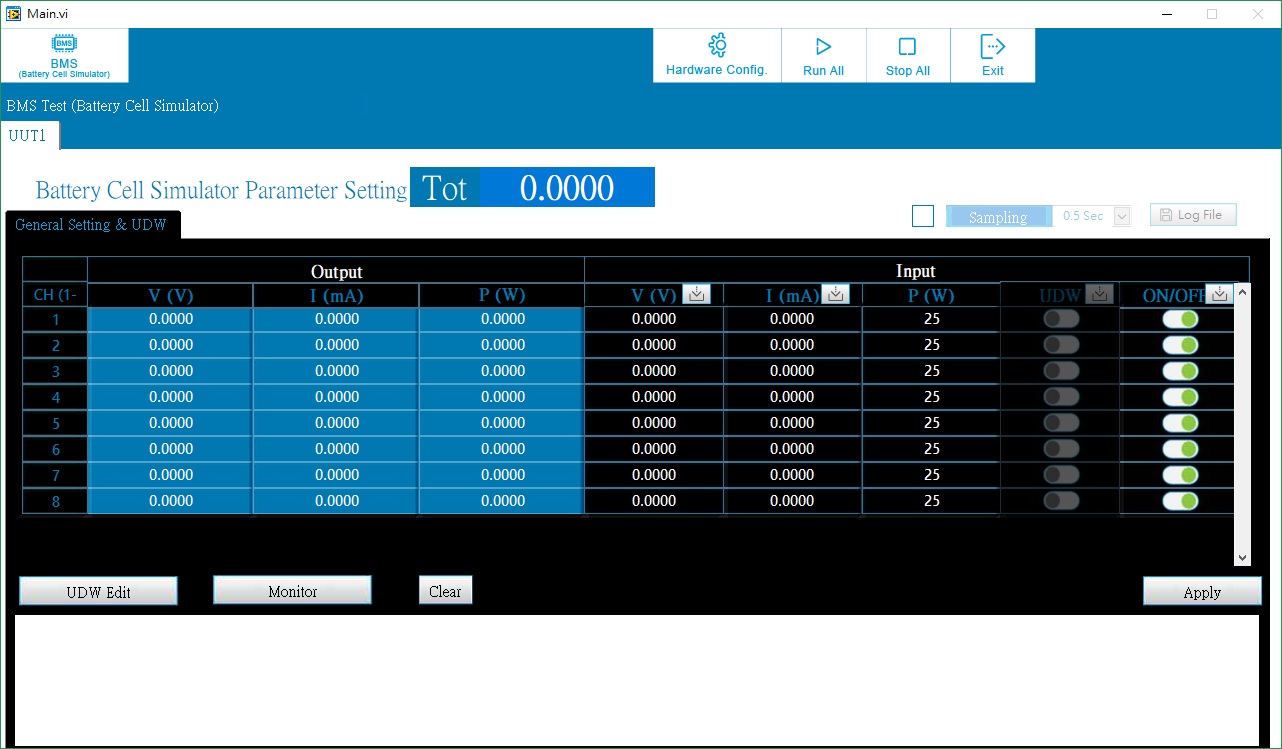

▲ 87001 Instrumentation Control Panel

Provide remote control of battery cell simulator from instrumentation panel

- Independently adjusts the voltage of each battery string

- Setting voltage change program: OVP/UVP/OVP release /UVP release test

Note: The instrumentation panel is only used on a single 87001 unit.

- Operation mode: constant current/voltage

- Channel power 25W

- Channel voltage 5V (can be connected in series)

- Channel current 5A (can be connected in parallel)

- Bi-directional power design

- Series and parallel coexistence function

- Simulates battery cell power for 480 battery packs in series (240 cells in series and 2 cells in parallel)

- Highly accurate current and voltage measurement

- Each channel has 4 current levels to choose from.

- Equalized flow design for parallel operation mode

- Fast voltage setting ramp-up/down speed: Time (1ms)

- Fast current switching between charging and discharging in current source mode without process interruption

- low output noise

- Independent channel over-voltage, current limit and over-temperature protection functions

- Standard Ethernet control interface

- CE marking

- BMS Battery Management System Test Validation

- Production testing of power tool products

| model number | relate (a story or information) |

| 870011 | 6-Channel Battery Cell Simulator |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.