TH9521/A comprehensive analysis system in a single machine to achieve AC withstand voltage, DC withstand voltage, insulation resistance, turn-to-turn insulation test, DC low resistance, inductance (TH9521A optional) test six functions. For coil components need to test items such as safety withstand voltage, turn-to-turn insulation, winding resistance value, coil inductance (TH9521A optional), previously required four different instruments to test separately, now in a single machine can be realized.

With the rich component analysis technology of Tonghui Electronics, TH9521/A brings more than just a simple superposition of four ordinary instruments: 500VA/200VA power AC design, 5kV AC/6kV DC output high voltage, insulation resistance voltage is increased to 5kV (TH9521), turn-to-turn insulation test voltage is increased to 6kV (TH9521), and the new high-voltage test fixture Realize four-terminal DC low resistance and test frequency up to 100kHz inductance test, the realization of new technology to bring better quality assurance for your products. Single machine equipped with eight-channel scanning interface, each channel can be set to high-end, low-end, off three states, can realize the test of up to eight groups of devices, to meet the user's application needs.

TH9521/A's simple and easy-to-use operation interface, eye-catching sorting result indication, perfect high-voltage protection, rich interface functions, convenient data transmission and data saving functions will simplify your testing process and greatly improve product testing efficiency.

Functional Features

A.500VA/200VA (TH9521A)Digital high power withstand voltage test:

Compared with the analog safety test principle, the digital withstand voltage test output high voltage is not affected by the utility power, the voltage quality is greatly improved, and at the same time, it can digitally display the real-time test voltage, so as to achieve more accurate measurement and display. Moreover, the output voltage adopts adaptive feedback control, so that changes in the output load will not cause changes in the output voltage.

B. Electric shock protection function

When the operator is in contact with the high-voltage output, the instrument will monitor whether the current flowing through the human body is too high, and if it is determined to be electrocution, the instrument will immediately cut off the output to protect the user's safety.

C. Open Short Circuit Detection Function (OSC)

In the process of voltage withstand test due to poor contact between the measured part and the test line, test line damage, etc., open-circuit phenomenon occurs, resulting in defective products misjudged as good products; damaged parts under test or the measured end of the spacing is too small, resulting in a short circuit of the test line phenomenon.

With the OCS function, TH9521/A can detect the open and short circuit conditions at the test end in advance, which reduces the occurrence of poor contact problems on the production line, protects the fixtures and equipment, and saves the test cost.

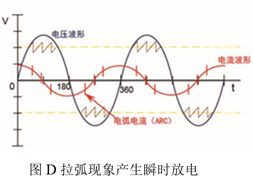

D. Arc detection function (ARC)

Poor voltage withstand refers to the occurrence of electrical flashover or insulation damage in the voltage withstand test. Nowadays, voltage withstand insulation test has become the standard equipment for all kinds of electrical equipment and insulation material safety test. However, just considering the insulation failure can not completely solve the product safety problems, another type of phenomenon, arc discharge ARC in the withstand voltage test is getting more and more attention, discharge and insulation capacity has a very high correlation between, so the ARC detection is the key to control the quality of the product.

Arc discharge occurs in the following two cases:

a) When the material is subjected to high voltage and the electric field strength is greater than the ionization energy of the gas, the gas on the surface of the material will undergo transient ionization phenomenon, which will result in the formation of flames on the surface of the material and the formation of temperature rise phenomenon on the material. Prolonged ignition and temperature rise may result in a qualitative change of the material, leading to insulation deterioration, a decrease in voltage tolerance, and ultimately insulation failure.

b) the detection of parts under test when the distance between the points is too small, in the parts under test at both ends of the higher voltage applied, the detection of the air at both ends of the space will be ionized, the formation of the phenomenon of ignition, that is, the phenomenon of pulling the arc. Arc phenomenon produces high-frequency transient discharge, in the test process produces a high-frequency current signal as shown in Figure D. Arc Detection (ARC) function is to use high-frequency power measurement to detect the way to determine whether the material insulation performance is bad.

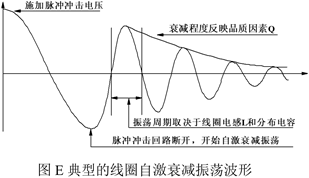

E. Coil pulse test function

This tester can effectively and non-destructively perform high-voltage pulse testing on coil windings to test their electrical performance. The principle is to apply the same pulse voltage to the coil winding under test and the standard coil winding, and compare the transient waveforms of the two to determine the merit of the winding under test. The transient waveform is also the attenuation oscillation waveform that occurs in the coil, which can simultaneously determine the inductance of the winding, the quality factor Q value, the number of turns of the winding, turn-to-turn layer-to-layer short-circuiting, more specifically, in the case of magnetically conductive materials, but also to determine the difference between the materials, etc.; high-voltage impulses under the corona discharge can also be the occurrence of layers of windings or a number of windings between the insulation is poor to determine.

The self-excited oscillation decay waveform in Figure E is directly related to the inductance value of the coil, L, and the quality factor, Q. The value of L and Q are inextricably linked to the number of turns of the coil, the manufacturing process, and whether or not it is a hollow coil, and also to the characteristics of the permeable material. Since the applied voltage is a high-voltage pulse voltage, short circuits in the coil, partial short circuits between turns, or corona discharges between layers or turns caused by insulation damage are naturally easy to detect.

F. DC Resistance Test Function (DCR)

The TH9521/A provides 8-channel, 4-wire DC resistance measurements, providing highly accurate testing of multi-winding devices such as motors and transformers, with measurement ranges from 0.01mΩ ~ 1.2MΩ.

a) DC resistance balance determination

The DC resistance of the motor winding is not balanced when it is easy to cause rotational imbalance, long-term use will cause damage, DC resistance balance function is the winding of the DCR maximum and minimum values are subtracted, if more than the range of the set value that is judged to be a defective product, is a motor class products long-term work reliability test aids.

b) Temperature compensation function

Measurement of smaller DC resistances often encounters large errors caused by temperature changes, so the TH9521/A incorporates a temperature compensation function. After conversion of the temperature coefficient the DC resistance is converted to the equivalent value at standard temperature, thus reducing the measurement error caused by temperature change.

G. Inductance Test Function

The TH9521 provides 8-channel, four-wire inductance measurements, providing highly accurate inductance measurements for transformers and other multi-winding devices. Constant 100 Ω source internal resistance, up to 100 kHz measurement frequency can meet most of the inductance test requirements.

| Product Model | TH9521 | TH9521A | |||||

| channel number | 8 | ||||||

| Pressure resistance test | |||||||

| output voltage | AC | 0.050 - 5.000kV, step 0.001kV, frequency 50Hz/60Hz ±0.1%, sine wave shape | |||||

| DC | 0.050 - 6.000kV in 0.01kV steps | ||||||

| accurate | ±(1% setpoint + 0.1% full scale) | ||||||

| adjustment rate | ≤ (1% output + 0.1% full scale) power rating | ||||||

| current range | AC | Voltage ≤ 4.000kV: 0.001mA - 120.0mA.

Voltage > 4.000kV: 0.001mA - 100.0mA. |

0.001mA - 40.0mA | ||||

| DC | 0.1μA - 20.00mA | 0.1μA - 10.00mA | |||||

| accurate | ±(1% reading + 0.5% full scale) | ||||||

| output power | AC | 500VA | 200VA | ||||

| DC | 120VA | 60VA | |||||

| ARC Arc | AC | 1.0mA - 20.0mA in 0.1mA steps | |||||

| DC | 1.0mA - 10.0mA, 0.1mA steps | ||||||

| Insulation resistance test | |||||||

| output voltage | range (of scales or measuring equipment) | 0.050 - 5.000kV in 0.01kV steps | 0.050 - 1.000kV in 0.01kV steps | ||||

| accurate | ±(1% setpoint + 0.1% full scale) | ±(1% setpoint + 0.1% full scale) | |||||

| Resistance Test Range | 0.100MΩ - 50.00GΩ Resolution: 0.1MΩ | 0.100MΩ - 10.00GΩ Resolution: 0.1MΩ | |||||

| Measurement accuracy | ≥500V | 1.000MΩ - 1.000GΩ, ± (3% reading + 5 words) | |||||

| 1.000GΩ - 10.00GΩ, ± (7% reading + 5 words) | |||||||

| 10.00GΩ - 50.00GΩ, ±(10% reading + 5 words) | |||||||

| < 500V | 0.100MΩ - 1.000GΩ, ± (7% reading + 5 words) | ||||||

| 1.000GΩ - 50.00GΩ, for reference only without accuracy requirements | |||||||

| time setting | |||||||

| rising time | OFF, 0.1s - 999.9s, step 0.1s | ||||||

| Testing time | 0.7s - 999.9s in 0.1s steps | ||||||

| descent time | OFF, 0.1s - 999.9s, step 0.1s | ||||||

| waiting time | OFF, 0.1s - 999.9s, step 0.1s | ||||||

| Turn-to-turn insulation test | |||||||

| Output pulse voltage | 0.1kV - 6.000kV, 0.01kV step, ±5% setting ±15V | 0.1kV - 3.000kV, 0.01kV step, ±5% setting ±15V | |||||

| Inductance Measurement Range | ≥10μH | ||||||

| pulse energy (physics) | Maximum 0.36 J | ||||||

| Waveform Sampling | Sampling rate: 12bit, Sampling speed: 200MHz, 8 adjustable steps, Storage depth: 12k Byte, Sample average: 1 - 32 | ||||||

| Number of pulses applied | Up to 32 | ||||||

| Method of determination | Area comparison, area difference comparison, corona discharge, phase difference comparison | ||||||

| OSC open/short circuit detection | |||||||

| Temperature compensation function | Optional Pt500A, temperature compensation, temperature conversion | ||||||

| DC Low Resistance Testing / △ & Y Resistance Testing | |||||||

| test signal | 100 mΩ 1A, 1Ω 0.5A, others ≤3V | ||||||

| Test Range | 0.01mΩ - 1.2MΩ | ||||||

| resistive | range (of scales or measuring equipment) | 0.01mΩ - 120.00mΩ | 0.1mΩ - 1200.0mΩ | 0.001Ω - 12.000Ω | 0.01Ω - 120.00kΩ | 0.1kΩ - 1200.0kΩ | |

| accurate | ±(0.5% reading + 0.04% full scale) | ±(0.3% reading + 0.03% full scale) | ±(0.2% reading + 0.03% full scale) | ±(0.1% reading + 0.03% full scale) | ±(0.2% reading + 0.03% full scale) | ||

| Inductive Testing | standard equipment | optional | |||||

| test parameter | Ls, Lp, Rs, Rp, Q | ||||||

| measurement accuracy | 0.5% | ||||||

| Test Frequency | 100Hz, 120Hz, 1kHz, 10kHz, 100kHz | ||||||

| Test Signal Level | 1.0Vrms, 10% Accuracy | ||||||

■ Six-in-one integrated test system, single machine to realize the coil class component testing needs:

1) High Power AC Withstand Voltage Analysis

2) DC withstand voltage analysis

3) Insulation resistance analysis

4) Turn-to-turn insulation analysis

5) DC Low Resistance Analysis

6) Inductance Testing and Analysis

■ Eight-channel scanning test, can test up to eight groups of devices simultaneously

■ 500VA power AC voltage withstand design, meet UL 1004-1 motor test standard

■ Insulation resistance test up to 5kV

■ DC/IR automatic rapid discharge function

■ Sampling ADC for turn-to-turn insulation testing upgraded to 12bit, 200MHz sampling rate

■ DC low resistance test support △Y-type motor DC resistance calculation

■ DC low resistance temperature conversion function, optional temperature sensor

■ Inductance test analysis up to 100kHz frequency

■ New high-voltage test fixtures: DC low resistance, inductance test four-terminal Kelvin test

■ Maximum test steps up to 32

■ High-resolution 7-inch 800 x 480 dot, TFT-LCD display

▪ Internal file storage and external USB flash drive file saving

■ Standard interfaces: HANDLER, RS232, USB HOST, USB DEVICE, LAN

Optional interfaces: GPIB, TC temperature probe

■ Comprehensive motor analysis tests

■ Comprehensive analytical testing of transformers

■ Comprehensive Inductance Testing

■ Charging pile inductance characteristics comprehensive analysis test

■ Comprehensive analysis and testing of magnetic components

| standard equipment | |||||

| Accessory Name | model number | ||||

| High Voltage Low End Test Cables | TH90019 | ||||

| High voltage test cable (with clamp) | TH90017A | ||||

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.